Views: 0 Author: Site Editor Publish Time: 2025-11-04 Origin: Site

In the fast-evolving landscape of modern manufacturing, precision, efficiency, and reliability have become the defining pillars of success. Traditional machining methods such as milling, turning, and drilling, though effective for many applications, face significant challenges when dealing with ultra-hard or delicate conductive materials. These contact-based techniques often introduce mechanical stress, tool wear, and thermal distortion—factors that limit the ability to achieve micron-level accuracy and smooth surface finishes.

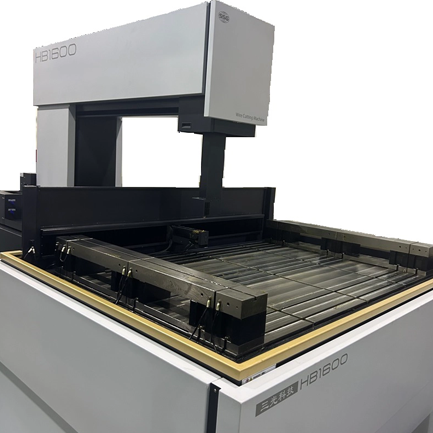

This limitation led to the rise of Electrical Discharge Machining (EDM), a groundbreaking non-contact process that removes material through controlled electrical discharges between an electrode and the workpiece. Among its variations, Wire EDM (Electrical Discharge Machining) stands out as a superior solution for producing intricate geometries, thin walls, and complex profiles in high-precision components.

Unlike traditional cutting, Wire EDM uses a continuously moving fine metal wire as an electrode, which emits high-frequency electrical sparks that erode the conductive material layer by layer. This process generates no direct mechanical force, allowing for extreme accuracy and superior surface quality—even on materials that are extremely hard or brittle.

However, the wire itself plays a decisive role in determining the success of the EDM process. The precision, stability, and efficiency of the cut depend on the wire’s electrical conductivity, tensile strength, diameter consistency, and thermal resistance. Among all available wire types, Molybdenum Wire EDM has emerged as a top choice for manufacturers aiming to optimize performance and quality in demanding production environments.

Precision cutting is the foundation of modern manufacturing, especially in industries such as aerospace, medical devices, semiconductors, and precision molds. Achieving consistent, micron-level accuracy requires a wire that can handle high thermal loads, maintain dimensional stability, and deliver uniform electrical discharge behavior throughout the cutting process.

Molybdenum Wire offers an exceptional combination of mechanical strength, electrical efficiency, and thermal resistance—making it uniquely suited for precision applications.

Wire EDM relies on millions of high-frequency discharges per second. Each spark removes a small amount of material, and the uniformity of these discharges determines the precision of the final cut.

Molybdenum Wire’s superior electrical conductivity ensures stable, evenly distributed sparks across the cutting zone. This minimizes micro-cracks, surface burns, and irregularities that can occur with less conductive wires such as brass or copper.

As a result, manufacturers can achieve smoother edges, tighter tolerances, and a more refined surface finish—critical for components used in medical, aerospace, and electronic applications.

Even minor fluctuations in wire diameter can cause deviations in the spark gap, leading to dimensional inaccuracies.

Molybdenum Wire, produced through advanced manufacturing and surface treatment processes, maintains exceptional diameter consistency—often within microns. This precision ensures that the spark gap remains constant, producing cuts that are geometrically accurate and repeatable across long production runs.

For industries requiring exact part matching or interchangeable components, such precision is indispensable.

One of Molybdenum’s most distinctive properties is its high melting point of 2623°C—far exceeding that of copper (1085°C) or brass (930°C). During Wire EDM, this means Molybdenum Wire can endure intense heat without softening, deforming, or breaking.

This thermal stability ensures that the wire maintains its structural integrity even under high-speed cutting conditions or prolonged use, resulting in stable machining and repeatable quality.

For precision manufacturing, where one micron of thermal expansion can alter part performance, this stability is a critical advantage.

Precision is only one side of the equation—efficiency and cost-effectiveness are equally vital in a competitive manufacturing environment. While achieving micron-level accuracy is essential, maintaining production speed, minimizing downtime, and optimizing material usage are what truly define a sustainable, high-performance production system.

Molybdenum Wire EDM stands out as a technology that not only delivers exceptional cutting precision but also transforms operational productivity across diverse manufacturing settings. Its unique combination of durability, reusability, and automation compatibility allows manufacturers to strike the ideal balance between accuracy and efficiency.

Traditional EDM wires such as brass or copper degrade quickly during high-load cutting operations. Frequent replacements interrupt the workflow, cause calibration delays, and reduce machine uptime. Each time a wire is replaced, the operator must pause the process, rethread the wire, and reestablish alignment—leading to a measurable drop in overall productivity.

In contrast, Molybdenum Wire exhibits an exceptionally low wear rate thanks to its superior hardness, tensile strength, and resistance to oxidation. Even under continuous use and elevated temperatures, it maintains its surface integrity and electrical properties far longer than conventional materials.

Because the wire wears slowly and evenly, cutting performance remains stable across multiple cycles. This durability means fewer wire changes, less machine downtime, and more consistent output per shift. For manufacturers operating in high-volume or automated production environments, these benefits translate directly into higher equipment utilization and reduced labor costs.

Moreover, the reduced need for frequent replacement wires lessens the risk of wire breakage during machining—one of the most common causes of production interruption. By extending the wire’s working life, Molybdenum Wire EDM effectively increases the uptime of every machine, helping companies meet tighter production deadlines with greater reliability.

One of the most compelling economic advantages of Molybdenum Wire EDM lies in its reusability. Unlike brass wire, which is typically used once and discarded, Molybdenum Wire can be cleaned, recoiled, and reused multiple times without compromising precision or surface quality.

This reusability can lead to substantial cost savings, particularly for manufacturers that operate numerous EDM machines or process high quantities of parts. Over time, material cost reductions can amount to a significant portion of a facility’s operational budget, improving overall profit margins.

In addition to its financial benefits, reusability also aligns with today’s growing emphasis on sustainable manufacturing. By minimizing wire waste and extending the material’s service life, companies can reduce their environmental footprint and comply more easily with green manufacturing standards. This dual advantage—cost efficiency and sustainability—makes Molybdenum Wire a smart choice for forward-thinking manufacturers seeking both economic and environmental performance.

Furthermore, Suzhou Sanguang’s advanced production technology ensures that each spool of Molybdenum Wire maintains consistent diameter, surface smoothness, and mechanical properties even after multiple uses. This consistency guarantees reliable EDM performance across repeated operations, ensuring that sustainability does not come at the expense of quality.

As global manufacturing moves increasingly toward automation, smart factories, and continuous production, reliability becomes a core performance metric. In this regard, Molybdenum Wire’s mechanical strength and heat resistance make it particularly suitable for automated long-cycle EDM systems.

During extended machining processes—often lasting several hours or even days—wire breakage or deformation can lead to significant production losses. The exceptional tensile strength and heat tolerance of Molybdenum Wire prevent such failures, ensuring uninterrupted operation and consistent cutting performance.

This characteristic makes it indispensable in industries such as semiconductors, aerospace, and precision molds, where complex geometries and tight tolerances demand sustained EDM operation without manual intervention.

Additionally, the smooth surface finish and stable electrical discharge provided by Molybdenum Wire contribute to uniform material removal, reducing the need for frequent adjustments or recalibration. These factors collectively enhance automation compatibility, enabling machines to run unattended for longer periods while maintaining superior cut quality.

For manufacturers deploying multiple EDM systems, the result is a dramatic improvement in overall equipment effectiveness (OEE)—a key productivity indicator that measures the combined impact of machine availability, performance, and output quality.

Molybdenum Wire EDM plays a vital role across industries that demand precision, durability, and efficiency.

Ideal for machining high-temperature alloys like titanium and Inconel, Molybdenum Wire EDM ensures accurate, stress-free cuts for components such as turbine blades and engine housings, maintaining superior surface integrity.

Its ability to create micro-scale, burr-free cuts makes it perfect for surgical tools and implants. The clean cutting process minimizes contamination and post-processing needs.

Molybdenum Wire supports ultra-fine detailing for micro connectors and circuit components, ensuring dimensional consistency and reliability in compact electronic designs.

In mold production, it delivers smooth surfaces and exact geometries, reducing polishing work and improving repeatability for high-volume manufacturing.

Molybdenum Wire EDM is redefining modern precision manufacturing with its exceptional accuracy, durability, and cost efficiency. By offering high thermal stability, superior conductivity, and low wear rates, it empowers manufacturers to achieve consistent results while reducing downtime and production costs. Its reusability and stability also support sustainable, automated, and high-volume operations—key factors in today’s competitive global market.

For companies aiming to enhance productivity and precision, Suzhou Sanguang Science & Technology Co., Ltd. provides advanced Molybdenum Wire solutions trusted by industries worldwide. With proven expertise, strict quality control, and custom-tailored wire options, Suzhou Sanguang helps manufacturers achieve reliable performance and long-term value.

To explore innovative EDM wire solutions or discuss tailored manufacturing needs, consider reaching out to Suzhou Sanguang’s expert team for more details.

Q1: Can Molybdenum Wire handle extremely intricate or micro-scale parts?

A: Yes. Its rigidity and thermal stability make it ideal for cutting micro features, thin walls, and complex geometries without deflection or loss of accuracy.

Q2: Is Molybdenum Wire suitable for high-temperature alloys like titanium or Inconel?

A: Absolutely. Its high melting point and thermal stability allow precise cutting of hard-to-machine, heat-resistant materials commonly used in aerospace and medical applications.

Q3: Can Molybdenum Wire EDM help manufacturers meet sustainability or green manufacturing goals?

A: Yes. Thanks to its reusability and reduced material waste, it aligns with eco-friendly production practices while maintaining precision and efficiency.

Q4: Is Molybdenum Wire suitable for automated, continuous operations?

A: Absolutely. Its rigidity, heat resistance, and stable electrical discharge make it ideal for long-cycle EDM systems in fully automated manufacturing environments.