A new generation of the molybdenum wire cut machine of HB800,perfect integrated design and minimized workshop space support you to realize the maxium production value.

Fully meet the latest National Standard JB/T11999.1-2014)

Challenge the limit of molybdenum wire cut machine and achieve the peak performance

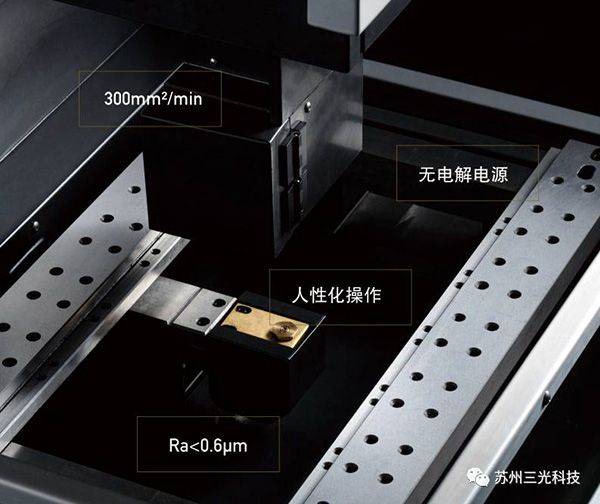

※ Best Surface Finish: Ra<0.6μm

※ Max. Cutting Speed : 300mm²/min

※ Original non-Electrolytic Power supply

※HB800Excellent Mechnical Highlights

Innovative Architechure

Four-axis AC servo with four-axis ball screw and linear guide rail, bringing unprecedented accuracy assurance.

Independent layout

X axis and Y axis independent layout, UV shaft truss structure to ensure high accuracy. The configuration of high quality castings and reinforcement can inhibit the deformation of the bed.

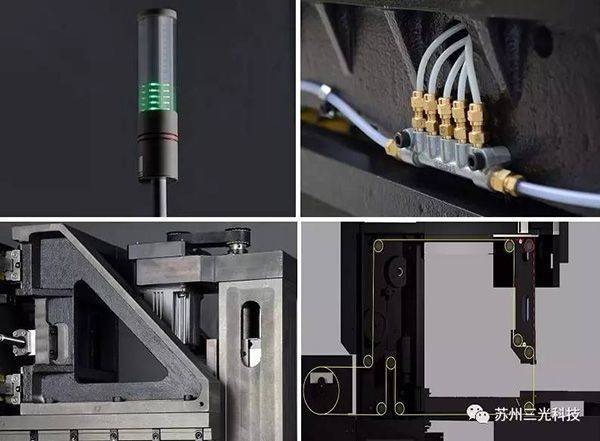

Protection Working Area

The frame water retaining structure makes cutting fluid no longer leaked. The lifting baffle is convenient for workpiece installation and saves space.

LED Lighting

LED lamp and working status indicator, always master the operation of the equipment.

Two ways of wire thread

Meet the different processing needs and very simple to replace the guide wheel.

Centralized Lubrication

Guideway and ball screw centralized lubrication, keep the workshop environment clean and tidy.

Guideway and ball screw centralized lubrication, keep the workshop environment clean and tidy.

Easy to use

The position of the console is adjusted at will and the control is handy.

The position of the console is adjusted at will and the control is handy.

※HB800Carefully Design System

Four-axis Mitsubish AC Servo Drive System

AC Servo drive system makes the cutting speed faster and the precision higher.

Intelligent Human-computer interaction system

Windows 7

Resolution display

Powerful process Parameter Library

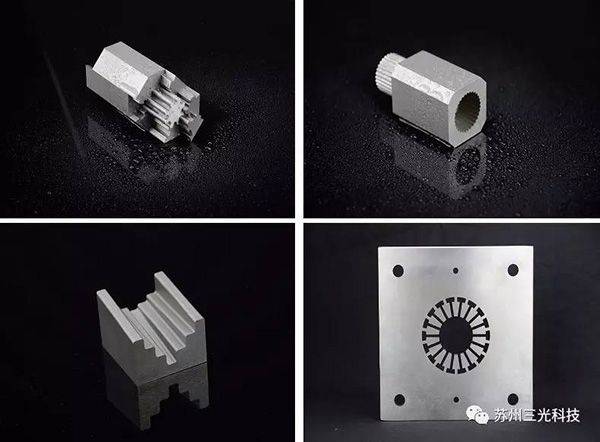

※HB800 Introduction processing cases

Die- Punch Tapper cutting

Workpiece thickness 40mm Workpiece thickness: 60mm

Material: SKD61 Material SKD11

Best Surface Finish: Ra<0.6μm Best Surface Finish Ra<0.8μm

Cutting numbers 4 Cutting numbers 4

Tolerance 5μm Tapper Angle±6º

※HB800 SPECIFICAITONS

Machine body

Worktable stroke(X,Y) 800mm*600mm

Wire Speed 1.18-11.8m/s

Machine weight 3710㎏/4000㎏

Machine Dimmension(L*W) : 2585mm*2535mm

Max.workpiece height 500mm

Max. Cutting Angle 20º/100mm

Worktable size 1710mm*935mm

Max.workpiece weight 2000㎏

Water tank

Filter accuracy 0.01mm

Capacity 130L

Working Methode Filtration System

Pulse Power

Max cutting speed ≥300㎜²/min

Best Surface Finish Ra≤0.6μm

Max. Cutting Currrent 12A

CNC System

Hardware Configurations: Industrial computer, LED display, Mitsubishi AC servo driver system, Schneider Inverter

Data Port USB, LAN

Programming Code: ISO code

Axis Numbers 5-axis and 4 axis simultaneous control, pitch compensation realized.

Menu Language Chinese/English/English (Inch)/ Italian/ Korean/Japanese

Aluminum cutting option

Power Supply

Power 3-380V±10% 50±1HZ

Working temperature 10-35℃

Consumption 1.2KVA

※OPTION:

Z axis CNC

Aluminum Cutting